A document affirming that a specific product design meets predetermined standards and regulatory requirements. This certification is granted following a thorough assessment of a representative sample of the product. For instance, a pressure vessel intended for use in a high-pressure environment would undergo rigorous testing to verify its compliance with relevant safety protocols before issuance of this form of attestation.

This form of certification is vital for ensuring consumer safety and product reliability. It provides assurance that a product has been independently evaluated and meets the necessary criteria for performance and safety. Historically, such certifications have been instrumental in fostering trust between manufacturers and consumers, reducing the risk of product failures and associated liabilities. This process often aligns with both national and international standards, facilitating global trade and standardization.

Understanding the specifics of the certification process is key for manufacturers seeking market access and for consumers making informed purchasing decisions. The following sections will delve into the specific regulations and standards governing the issuance of these attestations, exploring the steps involved in obtaining the certification and the ongoing responsibilities of the certificate holder.

1. Regulatory Compliance

Regulatory compliance mandates adherence to legally enforceable standards and requirements dictated by governmental bodies or industry-specific organizations. The issuance of a specific product design’s attestation is intrinsically linked to regulatory compliance; it serves as documented evidence that a product has been assessed and meets the stipulated safety and performance standards of a given jurisdiction or market. Failure to achieve regulatory compliance can result in significant penalties, including product recalls, fines, and restricted market access. For example, medical devices require this form of certification to demonstrate adherence to regulations like the European Union’s Medical Device Regulation (MDR) or the United States Food and Drug Administration (FDA) requirements, confirming that the product is safe and effective for its intended use.

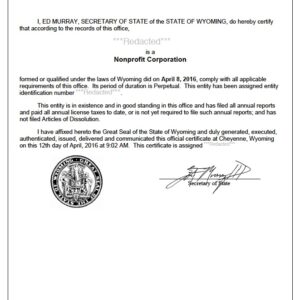

Suggested read: Get Your Wyoming Certificate of Good Standing Fast!

The significance of regulatory compliance within the attestation process extends beyond mere legal obligation. It promotes consumer confidence, encourages fair competition, and fosters innovation by establishing a level playing field for manufacturers. The process of obtaining the certification typically involves rigorous testing, meticulous documentation, and independent verification by accredited conformity assessment bodies. This third-party validation provides an unbiased assessment, further reinforcing the credibility of the certificate and ensuring adherence to established standards. Ongoing surveillance audits are often implemented to maintain certification validity, confirming continued compliance with regulatory requirements throughout the product’s lifecycle.

In summary, regulatory compliance is not merely a prerequisite for the attestation; it is a fundamental component that underpins its value and integrity. It guarantees that products placed on the market meet the necessary safety and performance criteria, thereby protecting consumers and fostering a robust and trustworthy marketplace. Challenges remain in navigating the complexities of differing regulatory frameworks across international markets, but a thorough understanding of these requirements is crucial for manufacturers seeking to successfully market their products globally.

2. Design Verification

Design verification constitutes a critical phase in obtaining a product design’s attestation. It is the process of confirming, through objective evidence, that the design outputs meet the specified design input requirements. In effect, design verification aims to answer the question: “Did we design the product correctly?”. This phase is intrinsically linked to the issuance of the certificate, as the certificate is a testament to the product’s conformity to pre-defined standards, and design verification provides the necessary validation that those standards are met at the design level. Without thorough design verification, the subsequent physical testing and assessment stages of the certification process would lack a solid foundation, potentially leading to inaccurate or unreliable results. For instance, the design of a new elevator braking system must be thoroughly verified to ensure it can reliably halt the elevator within specified parameters. Flawed design verification could lead to the catastrophic failure of the system, thus failing to obtain the certification.

Design verification typically involves a range of activities, including design reviews, calculations, simulations, and prototype testing. Each activity provides different forms of evidence to support the overall verification process. Design reviews offer a systematic assessment of the design by qualified experts, while calculations and simulations provide quantitative data to demonstrate performance under various conditions. Prototype testing provides empirical evidence of the design’s functionality and performance in a real-world setting. All these methods combine to provide a comprehensive view of the design’s strengths and weaknesses, ensuring that any potential issues are identified and addressed before the product proceeds to manufacturing and deployment. The documentation produced during design verification forms an integral part of the application for the certification, providing the certifying body with the necessary information to assess the product’s compliance with relevant standards.

In conclusion, design verification is not merely a preparatory step; it is a fundamental component of the attestation process. It provides the objective evidence necessary to demonstrate that the product design meets the required standards, ultimately ensuring product safety, reliability, and regulatory compliance. While robust design verification can be time-consuming and resource-intensive, the benefits of reduced risk, improved product quality, and streamlined certification processes far outweigh the costs. Navigating the complexities of various design verification methods requires a skilled and experienced team, highlighting the importance of investing in qualified personnel and robust verification processes. This ensures a successful certification outcome and bolsters the product’s long-term success in the marketplace.

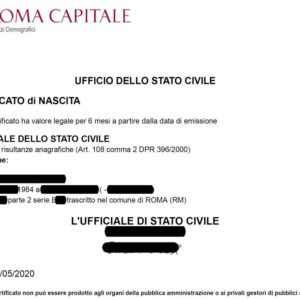

Suggested read: Email for Italian Birth Certificate? Get it Now!

3. Independent Assessment

The issuance of a design’s attestation hinges fundamentally on independent assessment. This element introduces an objective evaluation of the product against predetermined criteria, mitigating potential biases inherent in self-assessment or manufacturer-led evaluations. Accredited third-party organizations, devoid of affiliation with the product’s creator, conduct these assessments. This separation of assessment from development guarantees an unbiased validation of the product’s conformity to relevant standards. Failure to incorporate independent assessment would undermine the credibility and reliability of the attestation, rendering it a less valuable indicator of product safety and performance. For instance, pressure equipment intended for hazardous environments undergoes inspection by a Notified Body, an independent entity designated by a regulatory authority, to verify compliance with safety directives.

The practical significance of independent assessment lies in its role as a safeguard for consumers and end-users. By relying on objective evaluations, the attestation becomes a trusted indicator of product quality and safety. This trust extends to regulatory bodies and market stakeholders, facilitating smoother market access and reducing potential liabilities. Furthermore, independent assessment fosters competition among manufacturers by ensuring that all products are evaluated against the same rigorous standards. This promotes innovation and continuous improvement as manufacturers strive to meet or exceed these standards. The process often involves detailed documentation reviews, physical testing, and site audits, all conducted by qualified professionals adhering to strict ethical guidelines. The assessment culminates in a formal report outlining the findings, which serves as the basis for the certification decision.

In summary, independent assessment is an indispensable component of the attestation process. It provides the necessary assurance that a product has been rigorously evaluated by an impartial third party, guaranteeing its compliance with relevant standards and promoting consumer safety. Challenges may arise in selecting appropriate assessment bodies and navigating the complexities of diverse regulatory landscapes, however, the benefits of enhanced credibility and market access far outweigh these hurdles. The consistent application of rigorous, independent assessment procedures is essential for maintaining the integrity and value of the design’s attestation.

4. Safety Assurance

The issuance of a design’s attestation is intrinsically linked to safety assurance. The certificate serves as documented proof that a specific product design has undergone rigorous evaluation to verify its adherence to established safety standards. The attainment of the certificate is contingent upon demonstrating a robust level of safety assurance, encompassing design features, manufacturing processes, and intended operating conditions. The presence of the certificate, therefore, provides confidence that the product has been assessed and deemed safe for its intended use. Conversely, failure to meet safety requirements during the assessment process will preclude the issuance of the certificate. As an example, a new model of industrial robot would require the attestation to verify that its design incorporates adequate safeguards against hazards such as collisions, crushing, and electrical shock, thereby ensuring the safety of workers operating in proximity to the robot. Without this assurance, the robot could pose a significant risk to personnel and would not be eligible for the attestation.

The practical significance of understanding the relationship between safety assurance and the certificate lies in its implications for product liability and market access. A product bearing the attestation signals to consumers, regulators, and insurers that the manufacturer has taken appropriate steps to mitigate potential risks. This can reduce the likelihood of product-related incidents and associated legal repercussions. Furthermore, in many jurisdictions, the certificate is a mandatory requirement for placing certain types of products on the market. This underscores the importance of integrating safety considerations throughout the entire product development lifecycle, from initial design to final production. Ongoing surveillance and periodic re-certification are often necessary to maintain the validity of the certificate, ensuring that safety assurance remains a priority throughout the product’s lifespan.

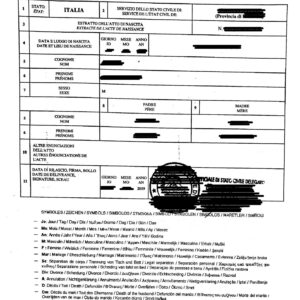

Suggested read: Get Ancestor's Birth Certificate Italy: Who to Email + Tips

In summary, safety assurance is not merely a desirable attribute; it is a fundamental prerequisite for obtaining a design’s attestation. The certificate acts as a verifiable testament to the product’s safety, fostering trust among stakeholders and facilitating regulatory compliance. Challenges remain in navigating the complexities of evolving safety standards and adapting to diverse regulatory landscapes, but the overarching principle remains constant: prioritizing safety is paramount to securing and maintaining the attestation, ultimately benefiting both manufacturers and end-users.

5. Market Access

The attestation directly influences market access for manufactured goods. This certification, a testament to a product’s compliance with specific standards, serves as a critical gateway to numerous markets. Regulatory bodies often mandate this certification as a prerequisite for product distribution and sale within their jurisdictions. Therefore, acquiring the certification is not merely a matter of adherence to voluntary guidelines, but frequently a legal necessity for entering and competing within a given market. A manufacturer of electrical equipment, for example, may find that without a valid certificate affirming conformity to relevant IEC standards, the product cannot legally be sold within the European Union.

The importance of this certification stems from its role in assuring regulatory compliance. Many markets, especially those within the European Union, utilize harmonized standards as a basis for demonstrating conformity with directives. The certificate provides verifiable evidence that a product has undergone rigorous testing and meets the stipulated safety, performance, and environmental requirements. This, in turn, streamlines the market access process, reducing the likelihood of delays or rejection by regulatory authorities. Moreover, possession of the certificate enhances a manufacturer’s reputation, bolstering consumer confidence and providing a competitive advantage in the marketplace. A well-recognized certification mark often serves as a powerful marketing tool, signifying quality and reliability to potential customers.

In conclusion, the certification plays a pivotal role in facilitating market access for manufacturers. Its status as a mandatory requirement in many markets, combined with its function as a verifiable demonstration of regulatory compliance, underscores its significance. While obtaining the certification can present challenges, including navigating complex regulatory frameworks and undergoing rigorous testing processes, the benefits of expanded market reach and enhanced brand reputation often outweigh these difficulties. Understanding and strategically pursuing the appropriate certification is, therefore, a crucial component of any successful market entry strategy.

Frequently Asked Questions About Type Examination Certificates

The following addresses common inquiries regarding design assessment documentation, clarifying its purpose, process, and implications.

Question 1: What exactly is a type examination certificate?

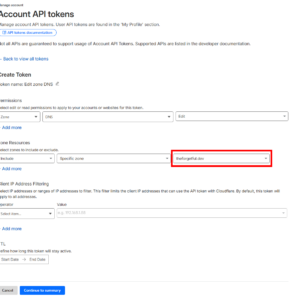

Suggested read: Quick Wget Ignore Certificate: The Simple Fix

It is a document issued by a notified body, attesting that a representative sample of a specific product design conforms to the essential requirements of relevant directives or standards. It does not constitute approval for mass production, but rather validation of the design itself.

Question 2: Which products typically require this form of certification?

A diverse range of products may necessitate this certification, often determined by regulatory requirements specific to the intended market. Examples include pressure equipment, machinery, electrical equipment, personal protective equipment, and medical devices.

Suggested read: Free Volunteer Certificate: Get Yours Now!

Question 3: Who is authorized to issue this attestation?

Only notified bodies, accredited by national accreditation bodies and designated by regulatory authorities, possess the authority to conduct type examinations and issue the associated certification.

Question 4: What steps are involved in obtaining this documentation?

Suggested read: Last Minute Valentines Gift Certificate - Now!

The process generally entails submitting a formal application, providing comprehensive technical documentation, furnishing a representative sample of the product, undergoing testing and assessment by the notified body, and addressing any non-conformities identified during the evaluation.

Question 5: Is this certification valid indefinitely?

The validity period varies depending on the specific directive or standard. Often, the certificate has a limited duration, necessitating renewal or re-certification to ensure ongoing compliance with evolving requirements.

Question 6: What are the consequences of lacking the necessary certificate for a product?

Suggested read: Printable Souvenir Birth Certificate Template - Fun Keepsake!

Selling or distributing a product requiring the certification without possessing a valid certificate can result in legal penalties, including fines, product recalls, and market access restrictions.

Understanding these points is crucial for both manufacturers seeking certification and stakeholders interpreting its significance. Adherence to established procedures is critical.

The next section will delve into the ongoing responsibilities associated with maintaining certificate validity and managing potential modifications to the certified product design.

Strategies for Navigating Design Assessment Documentation

The subsequent guidelines aim to provide manufacturers with essential insights into maximizing the benefits of acquiring and maintaining design assessment documentation, while also mitigating potential risks.

Tip 1: Prioritize Early Engagement with Notified Bodies: Commence discussions with potential certification bodies early in the product development cycle. This proactive approach allows for identification of applicable standards, clarification of testing requirements, and incorporation of design modifications necessary for compliance, minimizing costly rework later.

Suggested read: Get Your SC Resale Certificate: Guide & Apply Today

Tip 2: Maintain Meticulous Documentation: Comprehensive and accurate technical documentation is paramount for a successful assessment. This includes detailed design specifications, materials lists, manufacturing processes, test reports, and risk assessments. Inadequate documentation can lead to delays or rejection of the certification application.

Tip 3: Conduct Pre-Compliance Testing: Before submitting a product for formal assessment, conduct internal or third-party pre-compliance testing to identify potential non-conformities. This allows for proactive corrective actions, increasing the likelihood of a successful certification outcome.

Tip 4: Understand Scope Limitations: Be cognizant of the specific scope and limitations of the attestation. The certificate applies only to the specific product design and configuration tested. Modifications to the design or manufacturing process may necessitate re-certification.

Tip 5: Implement Robust Change Management: Establish a robust change management system to track and control any alterations to the certified product design. Document all modifications and assess their potential impact on compliance with the original certification standards. Significant changes may require notification to the certification body.

Tip 6: Ensure Ongoing Compliance Monitoring: Implement continuous monitoring processes to verify that the manufactured product continues to conform to the certified design and applicable standards. This may involve regular internal audits, supplier assessments, and routine testing.

Suggested read: Silver Certificate Values: Guide & Worth Today

Tip 7: Maintain Certificate Validity: Adhere to the requirements for maintaining certificate validity, including timely renewal, payment of fees, and participation in any required surveillance audits. Failure to comply with these requirements can result in suspension or revocation of the certification.

Adherence to these guidelines enhances the efficiency of the assessment process and mitigates the risk of non-compliance. The certification serves as a gateway to global markets and reinforces trust among consumers and regulatory bodies.

The concluding section will synthesize key insights from the preceding discussion and provide a final perspective on the strategic importance of the certification.

Type Examination Certificate

The preceding discussion has explored the multifaceted significance of the document asserting design validation. It has highlighted its role in demonstrating regulatory compliance, ensuring product safety, and facilitating market access. The issuance of a design’s attestation is not merely a procedural formality, but rather a substantive validation process affirming adherence to established standards and regulations.

Manufacturers must recognize the critical importance of meticulously navigating the certification process, from initial design verification to ongoing compliance monitoring. This rigorous approach is essential for mitigating potential risks, maximizing the benefits of the attestation, and upholding consumer trust. Prioritizing adherence to these stringent standards is crucial to securing long-term success and stability in an increasingly regulated global marketplace.