A formal document verifying the origin and characteristics of granular material, crucial in construction and manufacturing. This documentation confirms adherence to specific standards and specifications, potentially including particle size distribution, chemical composition, and physical properties. For instance, a construction project might require confirmation that aggregate used in concrete meets specified criteria for compressive strength and durability, which would be evidenced by this verification.

Such verification plays a significant role in ensuring structural integrity, environmental compliance, and consumer protection. Its existence mitigates risks associated with substandard or contaminated materials, preventing costly failures and environmental damage. Historically, the need for this type of assurance arose with increasing industrialization and the recognition that the quality of raw materials directly impacts the performance and longevity of finished products.

Understanding the criteria for issuing these documents, the potential for falsification, and the implications of using uncertified material are vital for stakeholders. Subsequent discussion will delve into the processes involved, legal frameworks governing these documents, and methods for verifying their authenticity.

1. Origin Traceability

Origin traceability constitutes a fundamental pillar of a reliable verification system, providing documented evidence of the material’s extraction point and chain of custody. This element is critical for enforcing regulations, mitigating environmental risks, and confirming the material’s legitimacy, all of which directly influence the value and acceptance of the document.

-

Geographic Source Verification

Suggested read: Get Your Wyoming Certificate of Good Standing Fast!

This aspect involves precisely identifying the extraction site, verifying it against authorized mining concessions, and documenting its adherence to environmental regulations. For instance, geolocation data and official permits may be included, ensuring that the material was not illegally mined from protected areas or sources implicated in environmental damage.

-

Chain of Custody Documentation

A complete chain of custody establishes a verifiable record of all transfers from the extraction site to the end user. This record includes details of transportation, processing, and storage, preventing the introduction of contaminants or the substitution of inferior materials. A detailed chain of custody can expose fraudulent activities, such as blending certified material with uncertified sources.

-

Environmental Impact Assessment

Verification of origin includes assessment and documentation of the environmental impact associated with the extraction process. Evidence of responsible extraction practices, such as site rehabilitation efforts, waste management protocols, and adherence to emission standards, supports sustainability claims. Failure to demonstrate environmental responsibility compromises the document’s credibility.

-

Regulatory Compliance Confirmation

Origin traceability necessitates demonstrating compliance with applicable regulatory frameworks governing extraction activities. This confirmation includes obtaining necessary permits, adhering to labor laws, and meeting environmental standards. Independent audits and government inspections may be required to ensure compliance, bolstering the authenticity of the document.

Suggested read: Email for Italian Birth Certificate? Get it Now!

These facets of origin traceability directly enhance the integrity and reliability of verification systems. By providing a verifiable connection between the material and its source, this traceability protects stakeholders from fraudulent practices, supports environmental conservation efforts, and promotes responsible resource management.

2. Compliance Verification

Compliance verification constitutes a crucial component in the issuance and validation of documentation. It establishes that the material adheres to specified industry standards, regulatory requirements, and contractual obligations. Without rigorous compliance verification, the documentation holds limited value, potentially leading to structural failures, environmental damage, and legal liabilities. As an example, construction projects often demand verification confirming the aggregate’s conformity to ASTM standards for particle size, density, and chemical composition. Failure to comply with these standards can lead to concrete mixtures with substandard strength and durability, jeopardizing the structural integrity of the building.

The verification process commonly involves independent testing and analysis conducted by certified laboratories. These labs employ standardized procedures to assess various material characteristics, issuing reports that confirm or deny compliance. Furthermore, auditing agencies may assess the supplier’s internal quality control systems to ensure consistent adherence to standards. In offshore drilling, for example, verifying compliance with environmental regulations regarding the composition of material used for seabed stabilization is critical to prevent pollution and ecosystem damage. The absence of thorough compliance verification creates vulnerabilities, potentially leading to the use of substandard or contaminated material.

Therefore, compliance verification is not merely a procedural formality; it is an indispensable safeguard that protects stakeholders. It provides assurance that the material meets the required quality and performance criteria, mitigating risks and promoting sustainable practices. The integrity and reliability of documentation are intrinsically linked to the rigor and transparency of the compliance verification process. Challenges remain in ensuring consistent enforcement and preventing fraudulent practices, highlighting the need for robust oversight and continuous improvement in verification methodologies.

3. Quality Assurance

Quality assurance (QA) is an intrinsic element in the validity and reliability of documentation. It provides systematic verification that the material meets predefined standards and specifications, minimizing potential risks and ensuring consistent performance.

-

Standardized Testing Protocols

QA relies on standardized testing protocols to objectively evaluate physical, chemical, and mechanical properties. These protocols, often dictated by ASTM or ISO standards, provide a uniform basis for comparison. For example, sieve analysis determines particle size distribution, while chemical analysis identifies the presence of contaminants. These tests, meticulously documented and referenced, are essential to maintain the integrity of the certification.

Suggested read: Get Ancestor's Birth Certificate Italy: Who to Email + Tips

-

Traceability and Documentation

A robust QA system maintains comprehensive traceability throughout the entire process, from extraction to certification. Detailed records of each step, including sampling procedures, testing dates, and personnel involved, are crucial for auditing and verification. Proper documentation enables identification of potential sources of error and facilitates corrective actions, reinforcing the reliability of the certification.

-

Calibration and Maintenance of Equipment

The accuracy of QA testing is directly dependent on the calibration and maintenance of testing equipment. Regular calibration using traceable standards ensures that measurements are accurate and reliable. Failure to maintain equipment integrity can introduce significant errors, compromising the validity of the documentation. Documented maintenance schedules and calibration records are essential components of a comprehensive QA program.

-

Independent Audits and Verification

Independent audits and verification provide an external assessment of the QA system, enhancing its credibility. These audits, conducted by accredited third parties, evaluate the effectiveness of the QA program and identify areas for improvement. Successful completion of an audit results in certification that the QA system meets recognized standards, bolstering confidence in the validity of the documentation.

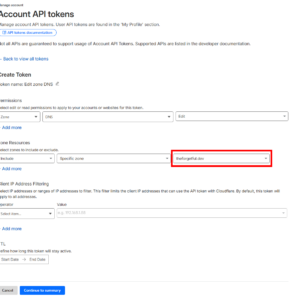

Suggested read: Quick Wget Ignore Certificate: The Simple Fix

These QA facets collectively contribute to a higher level of assurance. Stakeholders can confidently rely on the documentation to accurately reflect the material’s properties and suitability for specific applications, leading to reduced risks and improved performance.

4. Regulatory Adherence

Adherence to regulatory frameworks constitutes a cornerstone of a legitimate and credible documentation system. This compliance ensures materials meet established environmental, safety, and quality standards, safeguarding public health, promoting sustainable practices, and fostering fair competition within the industry.

-

Environmental Protection Laws

Environmental protection laws, such as those governing coastal zone management or endangered species habitats, directly influence extraction practices. Documentation must demonstrate compliance with these laws, providing evidence of adherence to permitted extraction zones, proper waste management protocols, and mitigation of ecological impacts. Failure to comply can result in significant fines, project delays, and reputational damage. For instance, extraction within designated marine protected areas would be a direct violation, invalidating any associated documentation.

-

Health and Safety Standards

Health and safety standards mandate the implementation of safe working conditions and the protection of workers involved in extraction, processing, and transportation. Documentation must confirm that suppliers adhere to these standards, including providing adequate personal protective equipment, implementing hazard control measures, and conducting regular safety training. Non-compliance can lead to workplace accidents, legal liabilities, and erosion of public trust. Examples include documenting compliance with OSHA regulations in the United States or equivalent standards in other jurisdictions.

-

Quality Control Regulations

Suggested read: Free Volunteer Certificate: Get Yours Now!

Quality control regulations stipulate minimum standards for the physical, chemical, and mechanical properties. The certification must reflect adherence to these regulations, providing evidence of regular testing, quality control procedures, and traceability of materials. Non-compliance can result in the use of substandard material, leading to structural failures, environmental contamination, and financial losses. For example, meeting the requirements of ASTM standards for aggregate used in concrete production falls under this category.

-

International Trade Laws

International trade laws govern the import and export of materials, ensuring fair trade practices and preventing illegal activities. Documentation must comply with these laws, including providing accurate information about the origin, composition, and value of the material. Non-compliance can lead to customs seizures, trade sanctions, and legal penalties. For example, demonstrating compliance with the Kimberley Process Certification Scheme for diamonds, which aims to prevent the trade in conflict diamonds, illustrates the importance of international trade regulations.

These facets of regulatory adherence underscore the critical role of a robust documentation system in ensuring responsible and sustainable practices. Compliance with these regulations not only mitigates risks but also promotes transparency, accountability, and trust within the industry. The integrity and reliability of documentation are directly proportional to the rigor and effectiveness of regulatory oversight.

5. Environmental Impact

The environmental impact of granular material extraction and utilization is inextricably linked to the issuance and credibility of a certificate. Extraction, processing, and transportation activities inherently disrupt ecosystems, alter landscapes, and contribute to greenhouse gas emissions. The documentation, therefore, must provide verifiable evidence of responsible environmental stewardship, addressing both direct and indirect consequences of these activities. Failure to adequately address the environmental impact renders the documentation incomplete and undermines its legitimacy. For instance, if a certificate does not demonstrate adherence to regulations regarding water usage during processing, or if it fails to document proper rehabilitation of the extraction site, its value is diminished.

The importance of environmental impact as a component of this certification lies in its function as a safeguard against unsustainable practices. The certification process should require comprehensive environmental impact assessments (EIAs) to identify potential risks and develop mitigation strategies. Real-life examples demonstrate the significance: projects involving dredging operations often necessitate detailed EIAs addressing potential impacts on marine life and coastal erosion. Similarly, land-based quarrying operations require EIAs evaluating effects on air quality, noise pollution, and habitat destruction. These assessments, and the mitigation measures implemented, must be transparently documented and verifiable to ensure compliance with environmental regulations and promote public trust. The absence of such documentation can lead to legal challenges, project delays, and long-term environmental damage.

In summary, the environmental impact is not merely a peripheral consideration but a central tenet of a meaningful certification. The certification must transparently demonstrate a commitment to minimizing ecological footprint through adherence to environmental regulations, implementation of robust mitigation strategies, and ongoing monitoring of environmental performance. Addressing the environmental impacts linked to the material source and processing enhances the reliability and credibility of the certificate, promoting sustainable practices and fostering responsible resource management. The challenges remain in consistently enforcing environmental standards and preventing falsification of documentation, emphasizing the need for rigorous oversight and innovative verification methodologies.

Suggested read: Last Minute Valentines Gift Certificate - Now!

Frequently Asked Questions Regarding Sand Certificate

This section addresses common inquiries concerning documentation related to granular materials, clarifying its purpose, scope, and significance.

Question 1: What constitutes a document?

A formal attestation verifying the source, composition, and characteristics of the granular material. It confirms adherence to relevant industry standards and regulations, guaranteeing suitability for specific applications.

Question 2: Why is such documentation necessary?

The documentation mitigates risks associated with substandard or contaminated materials, preventing structural failures, environmental damage, and legal liabilities. It provides assurance of material quality and compliance with established norms.

Question 3: What information typically is included?

Suggested read: Get Your Type Examination Certificate Fast!

Information encompasses the geographic origin, extraction methods, particle size distribution, chemical composition, physical properties, and compliance with relevant standards. It may also contain details regarding environmental impact assessments and mitigation strategies.

Question 4: Who is responsible for issuing such documentation?

Documentation is typically issued by independent testing laboratories, certification agencies, or suppliers with accredited quality control systems. The issuing body must possess the expertise and resources to conduct thorough testing and verification.

Question 5: How is the authenticity of the document verified?

Authenticity can be verified through several mechanisms, including cross-referencing with databases maintained by certification agencies, contacting the issuing body directly, and conducting independent testing of the material.

Question 6: What are the consequences of using materials lacking proper documentation?

Usage of uncertified material can result in structural failures, environmental contamination, legal penalties, and reputational damage. It compromises project integrity and jeopardizes the health and safety of stakeholders.

Suggested read: Printable Souvenir Birth Certificate Template - Fun Keepsake!

The validity of this documentation is contingent upon the rigor of testing, the credibility of the issuing body, and adherence to regulatory standards. Responsible procurement and usage of granular materials necessitate thorough verification of these documents.

Further exploration will delve into specific instances of falsification and methods to counter such practices, ensuring secure and reliable verification procedures.

Verifying Documentation

Ensuring the legitimacy and accuracy of this specific documentation is paramount to mitigating risks associated with substandard materials. The following tips offer guidance on verifying authenticity and minimizing potential issues.

Tip 1: Scrutinize the Issuing Body: Verify the accreditation and credentials of the organization that issued the verification. Independent testing laboratories or certification agencies should possess recognized certifications demonstrating competence and impartiality. Contacting accreditation bodies for confirmation is advisable.

Tip 2: Cross-Reference with Databases: Many certification agencies maintain online databases allowing for verification of document numbers and associated details. Utilize these resources to confirm the document’s existence and validate the information provided.

Tip 3: Examine Testing Methodologies: Ensure the testing methodologies employed align with relevant industry standards (e.g., ASTM, ISO). The report should explicitly state the testing methods used and provide detailed results, enabling comparison against acceptable limits.

Tip 4: Verify Chain of Custody: A complete chain of custody from extraction to delivery should be documented. Discrepancies or gaps in the chain of custody can indicate potential tampering or substitution of materials. Request documentation tracing the material’s origin and handling.

Suggested read: Get Your SC Resale Certificate: Guide & Apply Today

Tip 5: Conduct Independent Testing: For critical applications, consider conducting independent testing of samples by a trusted laboratory. This provides an additional layer of verification and confirms the material’s properties meet specified requirements.

Tip 6: Assess Regulatory Compliance: Confirm the material’s compliance with relevant environmental and safety regulations. The verification should reference specific permits, licenses, and compliance reports, demonstrating adherence to applicable legal frameworks.

Proper verification of the document safeguards against the use of substandard materials, protecting structural integrity, preventing environmental damage, and minimizing legal liabilities. Rigorous adherence to these guidelines ensures the reliability and trustworthiness of the certification process.

The subsequent section addresses the potential for fraudulent activity and explores methods for bolstering the security of documentation processes.

Conclusion

This exploration of the term sand certificate has emphasized its crucial role in ensuring quality, compliance, and sustainability within industries reliant on granular materials. The integrity of the document, achieved through rigorous testing, transparent origin tracing, and adherence to regulatory standards, directly impacts the structural integrity of infrastructure, the health of ecosystems, and the overall reliability of supply chains. Falsification or negligence in the verification process poses significant risks.

Therefore, continuous vigilance and investment in advanced authentication technologies are paramount. Stakeholders must prioritize the implementation of robust verification protocols and actively support initiatives aimed at strengthening the regulatory framework surrounding sand certificates. The future hinges on collective responsibility in upholding these standards to safeguard against economic losses, environmental degradation, and potential threats to public safety.