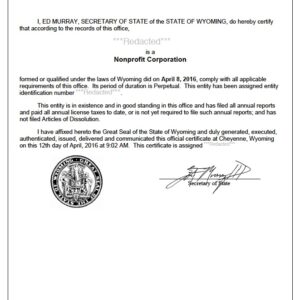

A mark or seal of approval, typically affixed to a product, document, or service, confirms adherence to established standards or regulations. For instance, equipment bearing a recognized safety validation mark indicates that it has undergone rigorous testing and meets specific safety requirements. This mark provides assurance to consumers or stakeholders regarding the quality, safety, or compliance of the item in question.

The presence of such validation offers numerous advantages. It instills confidence in the purchase or use of the certified item, mitigating risks associated with substandard products or services. Historically, these validations have served as a cornerstone of consumer protection and industry self-regulation, fostering trust and accountability. They also streamline processes, reduce liability, and can open access to new markets requiring validated compliance.

The subsequent sections will delve into specific types of validations and their applications across various sectors, examining the processes involved in obtaining them and their impact on both providers and end-users. These insights will offer a clearer understanding of the role and significance of validation in today’s complex and regulated environment.

1. Authenticity

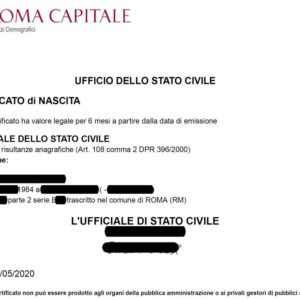

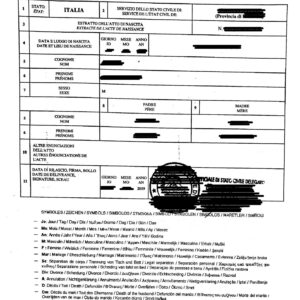

Authenticity, in the context of validations, represents the verifiable genuineness and legitimacy conveyed by the validation mark. It is a critical element, establishing the trustworthiness of a product, document, or service that bears the mark. This connection provides assurance against counterfeiting, fraud, and misrepresentation, thereby safeguarding consumer interests and maintaining market integrity.

-

Provenance Verification

Authenticity assures the confirmed origin and history of a product or document. For instance, a validation on a historical document could verify its age and authorship through rigorous forensic analysis. This verification process mitigates the risk of forged or misrepresented items entering the market or academic record, thus preserving accurate information and preventing fraud.

Suggested read: CPT Certification: What It Is & Why It Matters

-

Material Composition Confirmation

The validation process often includes analytical testing to confirm the claimed materials used in a product. A ‘certified organic’ validation on food products guarantees that the ingredients used meet specific organic farming standards. This assures consumers that the product is indeed made from the ingredients declared on the label, preventing deceptive marketing practices and promoting transparency in labeling.

-

Manufacturing Process Validation

Authenticity may extend to validating the integrity of the manufacturing process itself. For example, a validation on pharmaceutical products confirms adherence to Good Manufacturing Practices (GMP), ensuring that the drugs are produced under controlled and verified conditions. This validation helps to prevent contamination, ensure dosage accuracy, and ultimately safeguard patient health.

-

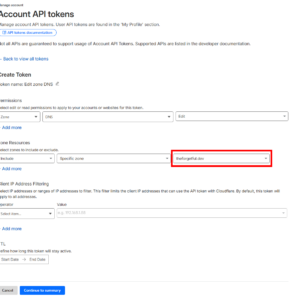

Digital Certificate Validation

In the digital realm, authenticity is often established through digital certificates that validate the identity of websites or software publishers. These certificates, validated by trusted Certificate Authorities, verify that the entity claiming to be the owner of a website or software is indeed who they claim to be. This helps prevent phishing attacks and ensures that users are interacting with legitimate sources, safeguarding their data and privacy.

These facets of authenticity collectively enhance the value and reliability of the validation mark. By validating the origin, composition, process, and digital identity, the validation ensures that the item bearing the mark is genuine and trustworthy. This bolsters consumer confidence, promotes fair trade practices, and helps to maintain the integrity of various industries, ultimately emphasizing the importance of a validation in todays world.

2. Compliance Assurance

Compliance assurance, inextricably linked to validations, denotes the guarantee that a product, process, or service aligns with relevant laws, regulations, and industry standards. The presence of a validation inherently signifies that the item has undergone scrutiny and satisfies the predefined criteria for legal and regulatory adherence. For instance, an electrical appliance featuring a validation from a recognized testing laboratory indicates that it meets established safety standards, ensuring compliance with electrical safety regulations in the designated market. This direct connection between the validation and compliance mitigates legal risks, protects consumers from potential harm, and fosters responsible business practices.

Suggested read: Get Wetland Delineation Certification: Your Path

The importance of compliance assurance within the validation framework is multifaceted. Firstly, it serves as a risk management tool, reducing the likelihood of legal penalties, product recalls, and reputational damage arising from non-compliance. Secondly, it facilitates market access. Many jurisdictions require validations as a prerequisite for importing or selling specific products, especially in sectors such as healthcare, automotive, and aerospace. The absence of a validation in these instances can effectively bar market entry. Thirdly, it promotes consumer trust and confidence. Consumers are more likely to purchase products bearing a validation mark, perceiving it as a reliable indicator of safety and quality. A validation on food packaging, for example, assures consumers that the product has been produced in accordance with stringent hygiene and safety standards.

In conclusion, the integration of compliance assurance into the validation process is essential for ensuring regulatory adherence, mitigating risks, and fostering consumer trust. The validation acts as a tangible representation of compliance, providing assurance to stakeholders and facilitating trade. The understanding and application of this connection is of paramount importance for manufacturers, regulators, and consumers alike, contributing to a safer, more transparent, and more accountable marketplace.

3. Quality verification

Quality verification, as an intrinsic component of a validation, represents the systematic assessment and confirmation that a product, service, or process meets predefined quality standards and specifications. The act of validation inherently necessitates a rigorous process of quality verification to ascertain that the criteria for a specific validation are indeed satisfied. For instance, a product seeking an ISO 9001 validation undergoes comprehensive quality management system audits, material testing, and performance evaluations to ensure conformity with the stringent requirements outlined in the ISO 9001 standard. The presence of the validation signifies the successful completion of these verification activities, providing assurance to stakeholders regarding the product’s adherence to quality benchmarks.

The link between quality verification and the presence of validation is bidirectional. The validation acts as an outcome of successful quality verification, while quality verification provides the evidentiary basis for issuing the validation. The absence of adequate quality verification would render the validation meaningless and potentially misleading. For example, a ‘Fair Trade’ validation on coffee beans implies that the producers have received fair compensation and adhere to ethical labor practices. This validation is predicated on rigorous audits of the supply chain, ensuring that the stated criteria are consistently met. Similarly, the Underwriters Laboratories (UL) validation on electrical appliances relies on extensive testing to ensure safety and performance, demonstrating a clear cause-and-effect relationship between quality verification and the issuance of the validation.

In summary, quality verification serves as the cornerstone of validation processes, providing the necessary evidence that standards have been met. The validation, in turn, acts as a visible declaration that such verification has occurred and that the associated quality requirements have been satisfied. This relationship bolsters consumer confidence, facilitates trade, and promotes responsible manufacturing practices across various industries. Failure to adequately implement quality verification processes undermines the integrity of the validation, eroding trust and potentially resulting in adverse consequences for all stakeholders.

4. Standard Adherence

Standard adherence forms the bedrock upon which the validity and reliability of a validation rest. It denotes the consistent and verifiable compliance with defined protocols, specifications, and requirements mandated by recognized standards bodies or regulatory agencies. In the context of a validation, adherence to standards is not merely a procedural step but rather the fundamental criterion that justifies the issuance and legitimacy of the mark.

-

Protocol Compliance

Protocol compliance necessitates that all processes, procedures, and methodologies employed in the creation, manufacturing, or delivery of a product or service conform precisely to the established protocols outlined within the relevant standard. For example, a validation under the Payment Card Industry Data Security Standard (PCI DSS) requires strict adherence to a detailed set of security protocols designed to protect cardholder data. Deviation from these protocols would invalidate the validation and expose the entity to significant financial and legal repercussions.

Suggested read: Get Your Tower Climbing Certification - Fast!

-

Material Specification Conformity

Material specification conformity ensures that all materials used in the production of a validated product meet the stringent requirements outlined in the relevant standard. Consider a validation in the construction industry, such as the validation for fire-resistant materials. These validations require that the materials used in construction meet specific fire-resistance ratings and composition requirements. Failure to conform to these specifications would jeopardize the integrity of the structure and render the validation invalid.

-

Performance Metric Thresholds

Adherence to performance metric thresholds mandates that a product or service consistently meets or exceeds predefined performance benchmarks established by the relevant standard. Energy Star validations, for example, require appliances to meet stringent energy efficiency targets. Manufacturers must demonstrate that their products consistently achieve these targets under standardized testing conditions to maintain the validation. Failure to meet these thresholds would result in the revocation of the validation.

-

Documentation and Record-Keeping

Thorough documentation and meticulous record-keeping are critical components of standard adherence, providing a verifiable audit trail that demonstrates compliance with the standard’s requirements. Validations under Good Manufacturing Practices (GMP) in the pharmaceutical industry, for instance, necessitate comprehensive documentation of every stage of the manufacturing process, from raw material sourcing to final product testing and packaging. This documentation serves as evidence of compliance during audits and inspections, ensuring the integrity of the validation.

In essence, standard adherence is not a static achievement but rather an ongoing commitment to maintaining compliance with established requirements. The validation serves as a visible attestation to this commitment, providing assurance to stakeholders that the validated product or service consistently meets the prescribed standards. Therefore, robust adherence to standards is crucial for upholding the credibility and value of the validation itself.

Suggested read: Get Certified: Tooth Gem Certification Online & More

5. Traceability

Traceability, in relation to validation, defines the capacity to track the history, application, or location of an item and its constituents through all stages of production, processing, and distribution. This is crucial for substantiating the claims made by a validation and ensuring accountability throughout the supply chain.

-

Source Material Identification

Traceability enables the identification and verification of source materials used in a validated product. For example, a “Forest Stewardship Council (FSC)” validation requires the ability to trace wood products back to sustainably managed forests. This ensures that the materials used comply with environmental and ethical sourcing requirements, bolstering the validation’s credibility.

-

Process Validation Linkage

A robust traceability system links specific manufacturing processes to individual validated items. In the aerospace industry, for example, components bearing a validation must have documented records of all manufacturing steps, inspections, and tests performed. This linkage provides a comprehensive history of the item’s production, ensuring quality and compliance throughout the manufacturing lifecycle.

-

Distribution Chain Accountability

Traceability extends beyond production to encompass the entire distribution chain. For instance, pharmaceuticals carrying a validation must be traceable from the manufacturing facility to the point of dispensing. This accountability helps prevent counterfeit drugs from entering the supply chain and ensures that legitimate products reach the intended recipients, safeguarding public health.

-

Recall Event Mitigation

Suggested read: Boost Your Career: THR Certification Guide

In the event of a product recall, traceability systems facilitate the swift and accurate identification of affected items. For example, in the automotive industry, vehicle identification numbers (VINs) enable manufacturers to trace specific components to particular production batches and distribution channels. This targeted approach minimizes the scope of the recall and reduces the potential for widespread disruption.

These facets of traceability collectively enhance the integrity and reliability of validations. By enabling the verification of source materials, manufacturing processes, distribution chains, and facilitating efficient recall management, traceability ensures that the claims made by the validation are substantiated and that accountability is maintained throughout the product lifecycle. The ability to trace an item’s history fosters trust among consumers, regulators, and other stakeholders, reinforcing the significance of traceability in the validation landscape.

6. Market Access

Market access, in the context of a validation, is fundamentally linked to a product’s ability to be legally sold and distributed within a specific geographical region or industry sector. A validation often serves as a gatekeeper, either facilitating or hindering entry into certain markets depending on regulatory requirements and consumer expectations.

-

Regulatory Compliance Enablement

Many jurisdictions mandate that certain products possess specific validations before they can be legally sold. For example, electrical devices often require validations from recognized testing laboratories to demonstrate compliance with safety standards, such as those set by UL or CSA. Without these validations, products may be barred from import or sale, effectively precluding market access.

-

Consumer Confidence Enhancement

Validations can significantly influence consumer purchasing decisions. Products bearing well-known and respected validations often enjoy a competitive advantage, as consumers perceive them as higher quality and safer. This increased confidence translates to greater market acceptance and penetration, opening doors to wider distribution channels and higher sales volumes.

-

Trade Barrier Reduction

Suggested read: Get SOTI MobiControl Exam Answers: Pass Certifications!

Mutual Recognition Agreements (MRAs) between countries often rely on the recognition of each other’s validations. If a product has been validated in one country according to mutually agreed standards, it may be accepted for sale in another country without undergoing further testing or validation processes. This reduces trade barriers and streamlines market entry, significantly enhancing market access opportunities.

-

Competitive Differentiation

In crowded marketplaces, a validation can serve as a key differentiator. Products that have undergone rigorous testing and validation processes can showcase their superior quality, safety, or performance compared to competitors that lack such validations. This differentiation attracts customers, retailers, and distributors, leading to increased market share and enhanced market access.

The strategic acquisition and display of appropriate validations are therefore vital for companies seeking to expand their market reach. The presence of a validation not only signifies compliance with regulations but also serves as a powerful marketing tool, influencing consumer behavior and facilitating entry into new and competitive markets. The alignment of a product with the relevant validations is often the key determinant of successful market access.

Frequently Asked Questions about Certification Stamps

The following questions address common inquiries regarding validation marks, their purpose, and their implications for products and services.

Question 1: What precisely defines a “certification stamp”?

A validation signifies an endorsement or guarantee that a product, service, or process meets specific predefined standards or requirements established by a recognized authority. It serves as a visible attestation of compliance and quality.

Suggested read: Ace Your SOTI MobiControl Exam | Certification Prep

Question 2: What benefits derive from products bearing validation marks?

Items displaying a validation often enjoy increased consumer confidence, reduced liability for manufacturers, facilitated market access due to regulatory compliance, and a potential competitive advantage over non-validated products.

Question 3: Who are the issuing bodies for validations?

Issuing bodies can vary widely, including governmental agencies, independent testing laboratories, industry associations, and standards organizations. The specific issuing body depends on the product type, industry, and geographic region.

Question 4: How does an item acquire a validation?

Obtaining a validation typically involves submitting the product or service to a designated testing or assessment process, demonstrating adherence to the relevant standards. This may involve inspections, audits, testing, and documentation review.

Question 5: Is a validation mandatory for all products?

Mandatory validation requirements vary depending on the product type, industry, and jurisdiction. Certain products, such as those related to safety or health, may be legally required to possess specific validations before being sold.

Suggested read: Pass SOTI 15 Exam: Answers & Tips! (2024)

Question 6: What is the duration of a validation validity?

The validity period of a validation can vary, ranging from months to years. Some validations require periodic renewal or re-assessment to ensure continued compliance with the relevant standards.

In summary, validations provide critical assurance of quality, safety, and compliance. Understanding the nuances of validations and their implications is essential for both producers and consumers.

The subsequent sections will delve into specific industry applications of validation and the processes involved in maintaining validation integrity.

Guidance on Validations

The following section offers pivotal guidance related to validations, particularly focusing on considerations for businesses and consumers interacting with validated products and services.

Tip 1: Verify the Authenticity. Prior to reliance on a validation, independently verify its legitimacy. Consult the issuing body’s official registry or website to confirm the validation’s current status and scope. Counterfeit validations can mislead and expose parties to risk.

Tip 2: Understand the Scope. A validation does not inherently guarantee all aspects of a product or service. Ascertain precisely what the validation covers. A safety validation may not address performance characteristics, for example.

Tip 3: Consider the Issuing Body’s Reputation. The credibility of a validation is directly proportional to the reputation and rigor of the issuing organization. Research the issuing body’s history, accreditation, and industry standing before placing undue confidence in its validations.

Suggested read: Fast Smog Certification Fremont: [Shop Name] Approved!

Tip 4: Review Underlying Standards. Familiarize oneself with the specific standards or criteria that the validation signifies compliance with. A general understanding of these standards provides a more informed basis for evaluating the product or service’s merits.

Tip 5: Remain Vigilant. Validations are not immutable. Monitor the validation’s expiration date and be aware of any reported incidents or recalls associated with the validated product or service. Continued vigilance is essential to maintaining confidence.

Tip 6: Traceability. Understand the origins of products carrying a certification. A transparent supply chain assures quality, prevents counterfeiting, and strengthens consumer trust. Prioritize purchasing from suppliers with complete traceability information.

These recommendations facilitate a more informed and discerning approach to engaging with validated products and services. By exercising due diligence, stakeholders can mitigate risks and ensure that validations serve their intended purpose.

The concluding segment will summarize the key takeaways and provide an overarching perspective on the value of understanding validations.

Conclusion

This exploration has elucidated the multifaceted nature of the validation, revealing its critical role in establishing trust and facilitating trade across diverse sectors. The validation, represented by a physical or digital insignia, provides verifiable assurance of standard adherence, quality verification, and compliance assurance, thereby mitigating risks for both producers and consumers. Its presence often unlocks market access and enhances competitive positioning. Traceability further bolsters the validation’s integrity, allowing for accountability throughout the product lifecycle.

Understanding the significance of the validation is paramount in today’s complex regulatory and commercial landscape. Stakeholders are encouraged to exercise diligence in verifying the authenticity and scope of validations, recognizing that informed decisions are essential for safeguarding interests and fostering a more transparent and accountable marketplace. Ongoing vigilance regarding validation standards and issuing body credibility will remain crucial for maintaining the integrity of the system and protecting the value it represents.